Transverse Profiling System

The Ames Transverse Profiling System is the latest innovation to complete your asset management data collection. It collects the entire lane width as you drive, and can be used to measure many roadway features, including - rutting, lane markings, visual crack inspection and edge drop-offs.

The system uses a single laser and high speed camera to capture 3D transverse profile data at highway speeds. Capable of being either integrated with our High Speed Profiler or used as a standalone unit, it easily installs onto your host vehicle making it one of the most cost effective solutions for pavement condition data collection.

System Overview

- - Portable system easily installs onto host vehicle using standard mounting hardware

- - One compact sensor unit capable of covering entire lane 13′ width (4m)

- - Uses a standard ruggedized laptop computer for data collection and analysis

- - Comprehensive analysis software for post collection viewing and analyzing of pavement condition data

- - Different systems designed to meet your needs & budget

Transverse Profile & Rut System – 2K Features

- - Collects surface image, lane markings, rut data, sealed & unsealed crack detection

- - 2,048 Points / Profile

- - Sample Rate – 2,500-4,000 Profiles / second

- - Travel Speed – 60 mph

- - Longitudinal Spacing – 0.25 – 0.5 inch

- - Transverse Coverage – 13 feet

- - Transverse Resolution – 1.95mm

- - Vertical Range +/- 4 inches

- - Vertical Resolution – 0.65 mm

Transverse Profile & Rut System – 4K Features

- - Collects the best surface image, lane markings, rut data, sealed & unsealed crack detection and estimated macrotexture

- - 4,096 Points / Profile

- - Sample Rate – 2,500 – 4,000 Profiles / second

- - Travel Speed – 60 mph

- - Longitudinal Spacing – 0.1 – 0.2 inch

- - Transverse Coverage – 13 feet

- - Transverse Resolution – 1.95mm

- - Vertical Range +/- 4 inches

- - Vertical Resolution – 0.30 mm

Additional Features

Vehicle Mount

The “Transverse Laser Sensor” is designed for quick and secure installation on your vehicle using standard mounting hardware. Its setup ensures seamless integration, making it a reliable choice for precision measurements in the field.

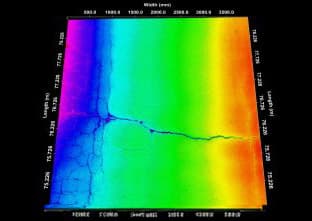

3D Model View

The 3D mode capability enhances surface analysis, aiding in efficient maintenance planning and decision-making. It generates detailed color maps of pavement surfaces to visually identify and accurately assess distressed areas.

3D Range View

The 3D Range View provides identification of pavement distress, cracking, potholes, and raveling, all paired with geo-referenced location data.

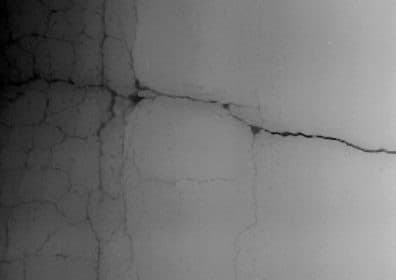

3D Intensity View

The 3D Intensity View delivers high-resolution imaging, enabling detailed visualization and accurate identification of various types of pavement distress.