Onsite Demonstrations and Consultation

Foremost in developing sensor technology for pavement measurements.

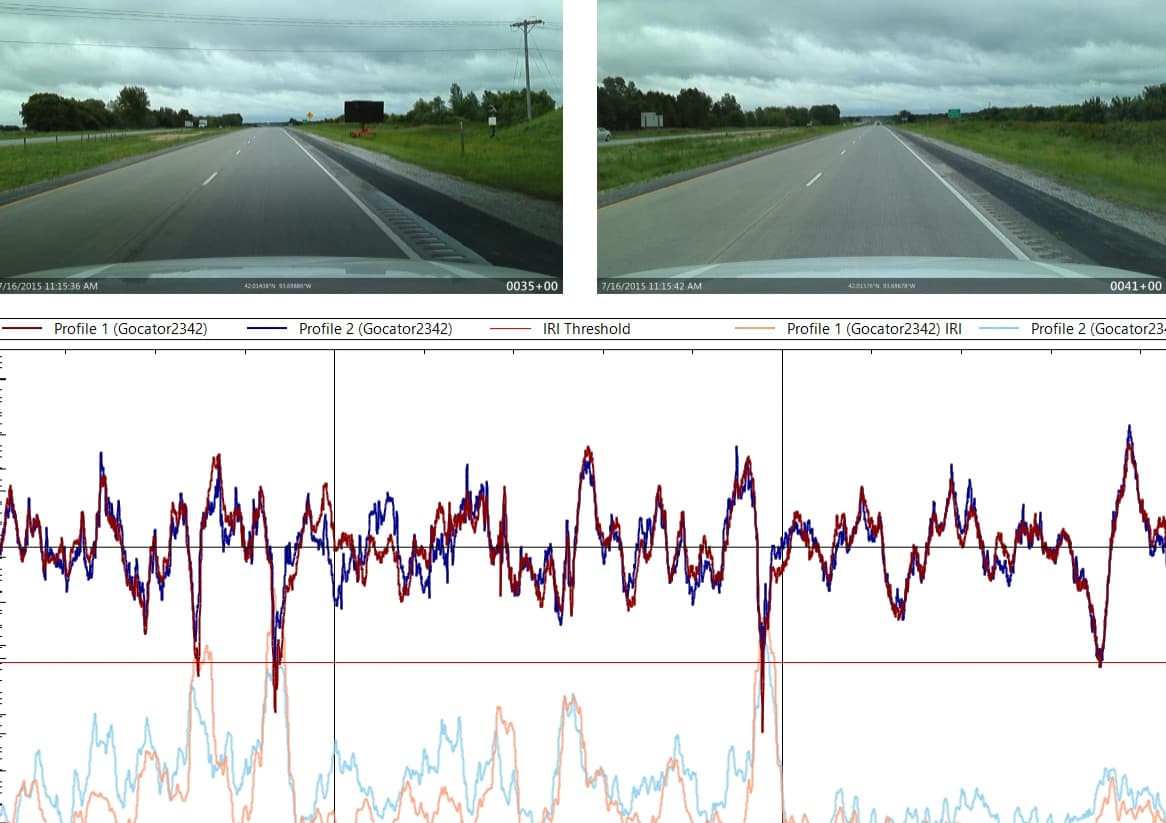

High Speed Inertial Profiler

Model 8300

New Product!

Stop and Go Inertial Road Profiler

Model 8300

Transverse Imaging System

Rut Depth Measurement

Lightweight Inertial Profiler

Model 6300

Laser Texture Scanner

Model 9400HD

Rapid Texture Scanner

Model 9500

Real Time Profiler

Model 7200 RTP

Pro GPS-DMI

Pro GPS-DMI Options

Concrete Line Laser

LMI 5K Gocator

AccuTexture 100

Acuity AR550

Software

Data Management